Two-Photon

Polymerization

(TPP)

Two-Photon

Polymerization (TPP)

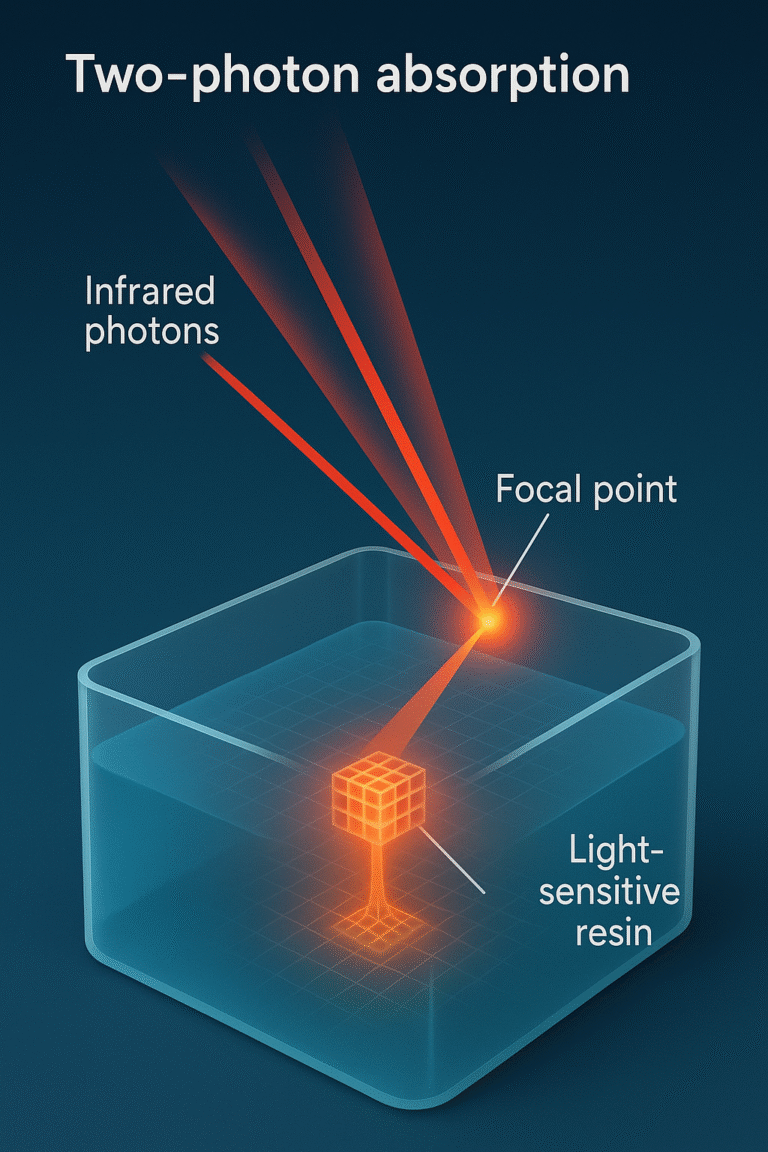

Two-Photon Polymerization (TPP) is a revolutionary 3D micro/nanofabrication technology that overcomes the limitations of traditional manufacturing methods by enabling the creation of intricate three-dimensional structures with feature sizes down to 100 nanometers.

TPP has demonstrated significant potential in a variety of fields, including miniaturized optical components, biomedical devices, MEMS, and quantum optics.

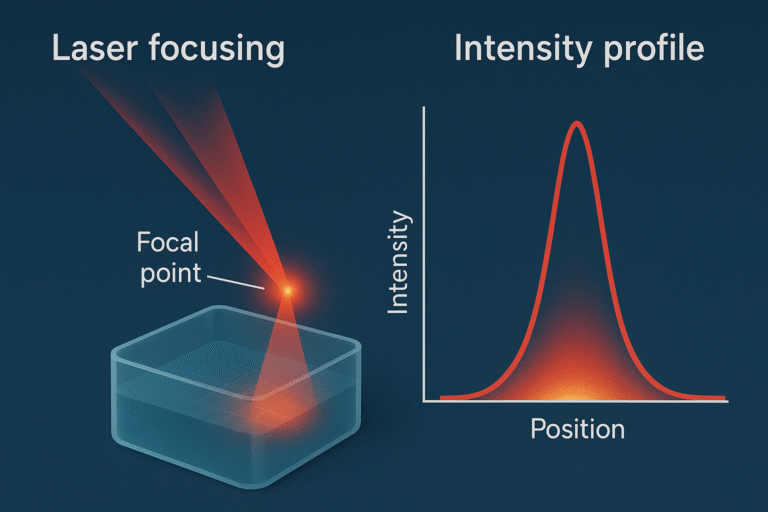

Unlike conventional photopolymer-based 3D printing, which relies on layer-by-layer accumulation, TPP leverages the nonlinear effects of quantum physics to initiate polymerization precisely at any point within the photosensitive resin — essentially performing “3D sculpting” at the microscopic scale.