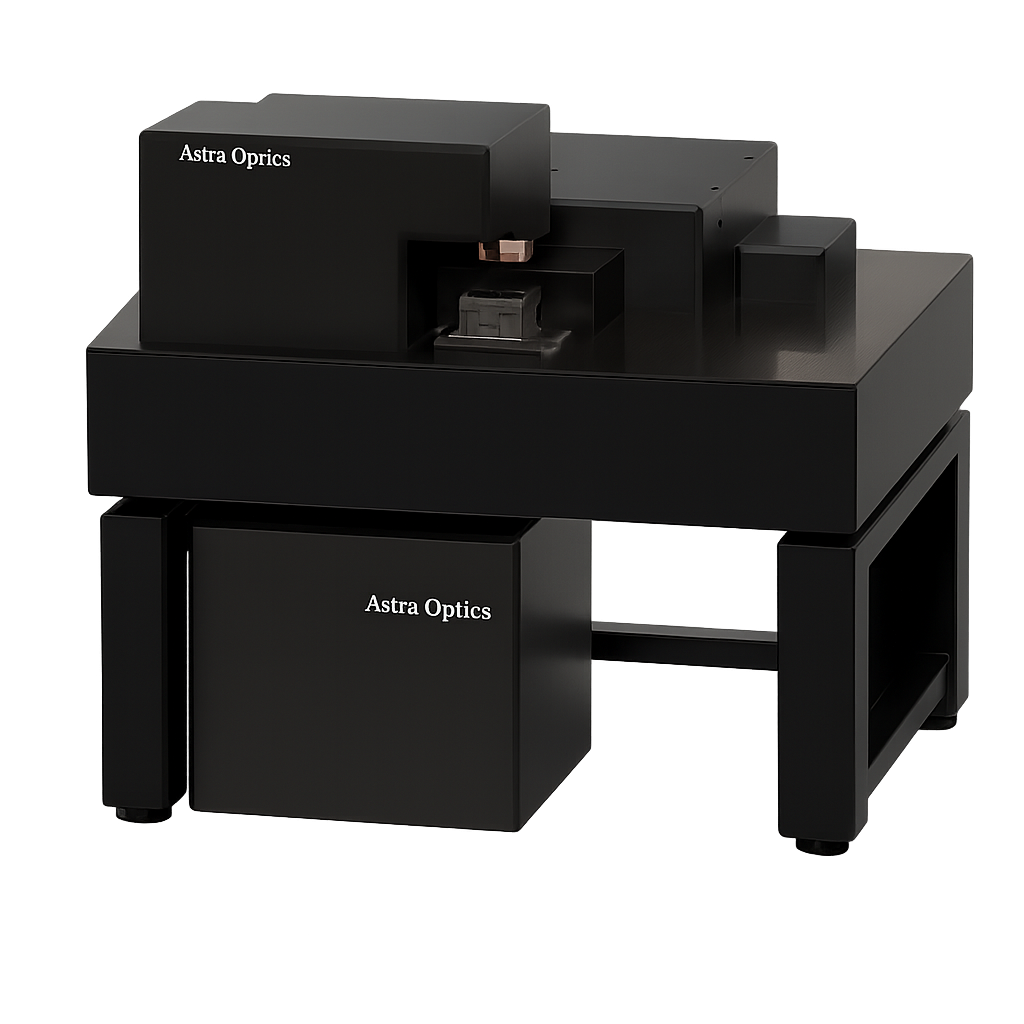

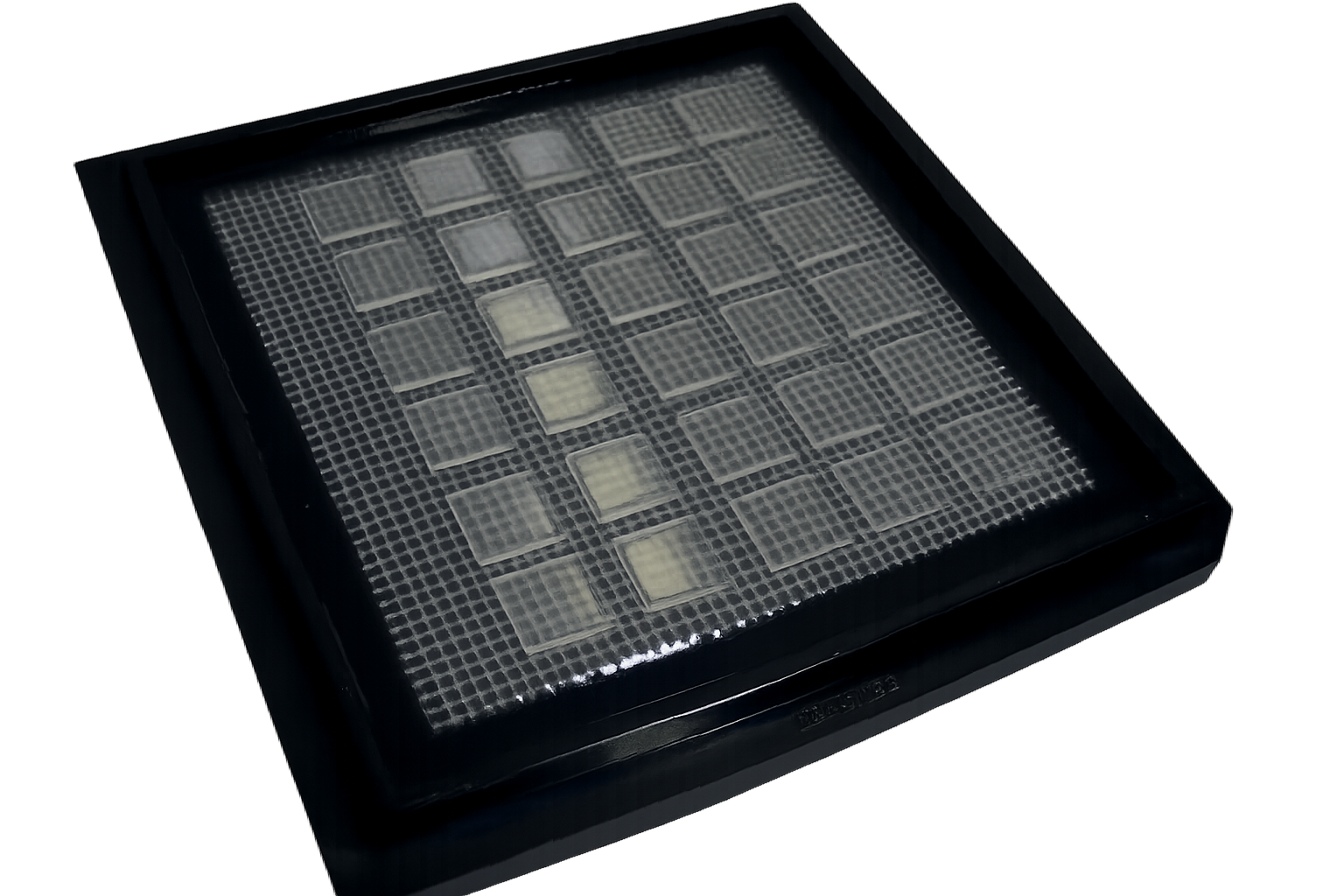

FP Nano Printer

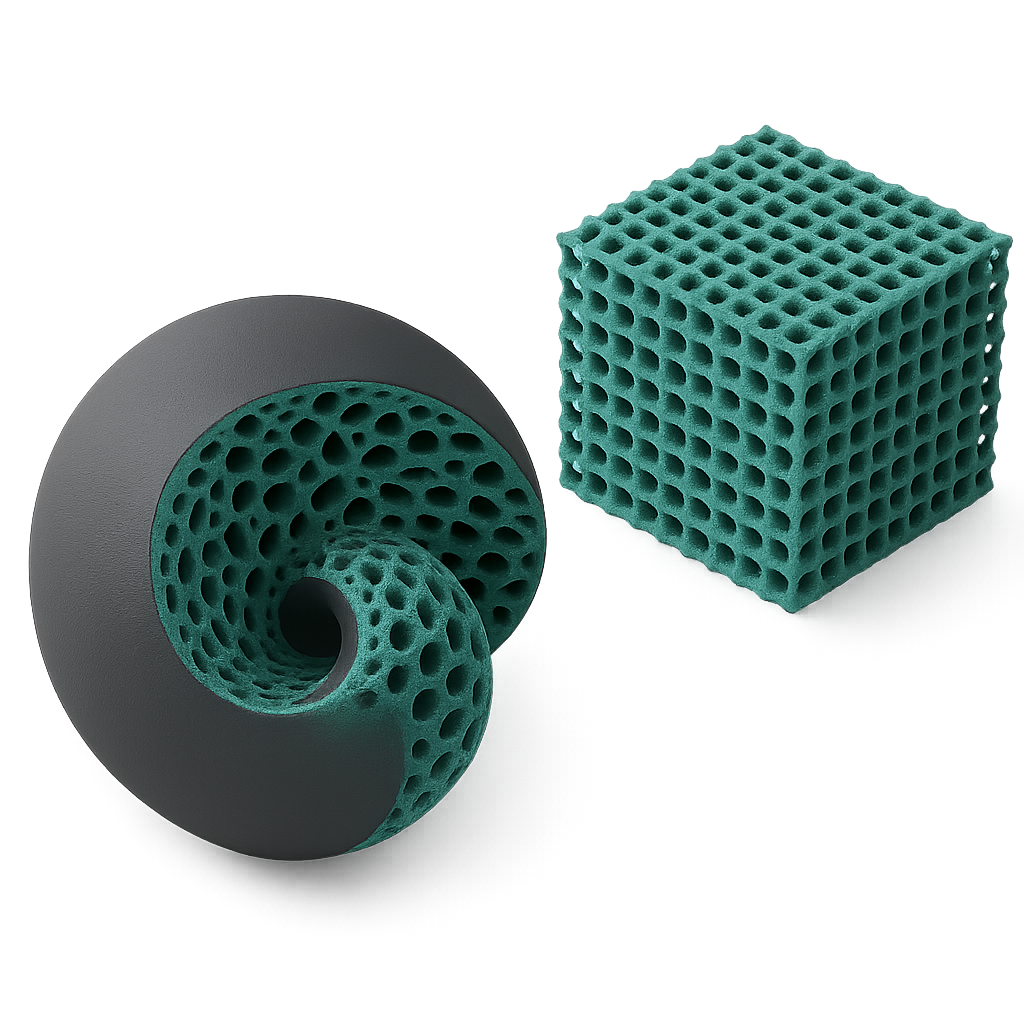

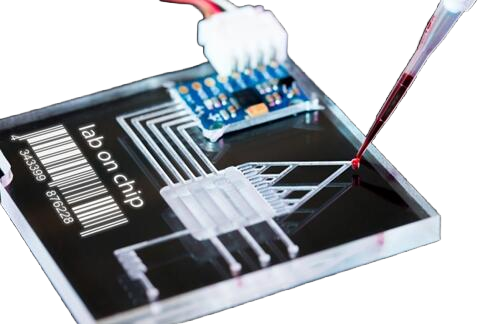

With its high resolution, processing efficiency, and cost-effectiveness, the FP NanoPrinter enables the first industrial-scale implementation of multi-material nanomanufacturing.

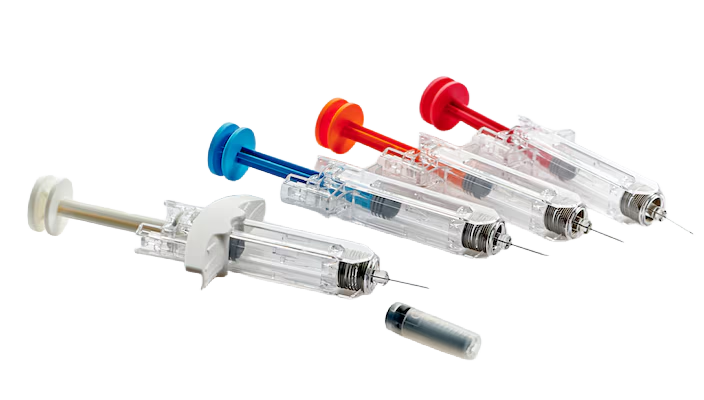

It holds transformative potential across a wide range of sectors, including nanotechnology, biotechnology, healthcare, renewable energy, and electronics.